Climate change is a fact of our lifetimes as we have all witnessed and experienced the disasters brought on by global warming. In the recent past, we have made significant progress in transitioning to renewable energy. But this only solves half of the problem. To effectively combat climate change, we must find sustainable materials and circular processes.

The common link between the industries is the use of plastics, which is the primary reason for their greenhouse gas emissions and, in turn, their carbon footprint. The average carbon footprint on a global scale is closer to 4 tonnes. By 2050, the average worldwide carbon footprint per year must be under 2 tonnes to have the best chance of averting a 2°C rise in global temperatures. The Paris Agreement states that if global temperatures rise above the 1.5 °C mark, it could have catastrophic effects on our environment. 4.5 per cent of the global CO2 emissions are caused by the manufacturing, consumption, and disposal of plastics. The plastics economy has reached a scale of over $2 trillion, globally.

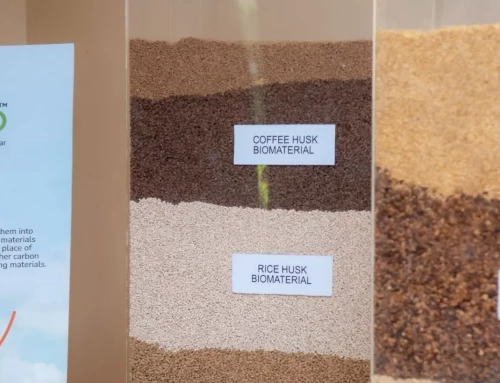

In addition to the emissions from plastic, India produces more than 500 million tons of crop waste every year and about 2/3rds of this waste is either burnt or discarded, resulting in further greenhouse gas emissions. Instead of burning, finding novel ways to use crop waste can potentially arrest 25 per cent of India’s carbon emissions.

Companies and businesses have come forward and realised that they need to sustain and ensure that they do not have any negative impact on society. Businesses now are working to achieve the goal of removing carbon footprints and leaving behind green footprints. To achieve this goal technology has also been essential.

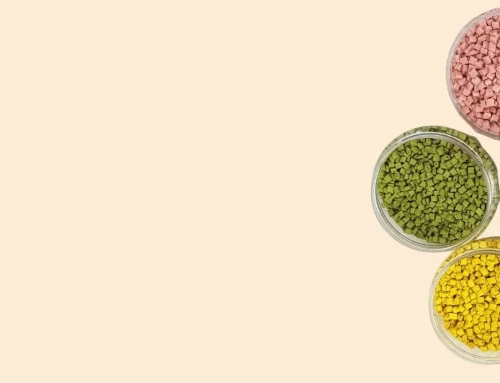

One such company is Mynusco a biomaterials platform for circular Bio-economy. They are enabling the transition of the plastics economy into a sustainable future. They have prevented 500 tons of CO2 emissions, which equals the emissions from 350 cars in a year. Bangalore-based company Mynusco is the world’s first biomaterial company to use Artificial Intelligence is being used to choose the right environment-friendly material and Block chain to dynamically track the carbon footprint and resource stewardship across the product lifecycle. They manufacture bio composite materials out of crop residue and fast renewables such as rice husks, rice straws, coffee husks, and bamboo waste to make their biomaterials. Mynusco has successfully helped companies across the automotive, consumer goods, furniture, personal care, packaging, and hospitality sectors implement circular solutions with their biomaterials platform.

Reducing unnecessary energy inefficiencies is a vital step to minimizing your carbon footprint. Shifting the energy mix away from fossil fuels and toward zero-emission electricity and other low-emission energy sources like hydrogen; adapting industrial and agricultural processes; increasing energy efficiency and managing demand for energy; utilising the circular economy; consuming fewer emissions-intensive goods; and deploying carbon capture are all effective ways to accelerate decarbonisation.

(The given article includes inputs from Mahadev Chikkanna, Founder & CEO, Mynusco and has been created exclusively for BW Disrupt)